Metal Steel Cast Steel Grit for Shot Blasting and Polishing

1.PICTURES OF STEEL GRIT

2.SPECIFICATION OF STEEL GRIT

3.APPLICATION OF STEEL GRIT

1.Cleaning: blast cleaning, steel blasting cleaning, casting, die casting, forging, forging the shotblast cleaning, the shotblast cleaning steel blasting plate for castings deoxidization, cleaning, cleaning, clean, H section steel, steel structure.

2.Derusting: blast cleaning, blast cleaning, casting rust, forgings, rust removing, forgings, iron removal, steel derusting, h-steel derusting, steel structure derusting.

3.Reinforcement: heat treatment part shot shot strengthening, gear shot strengthening.

Steel grit blasting: shaped steel grit blasting, steel grit blasting, ship plate shot blasting, steel plate spray shot, steel grit blasting.

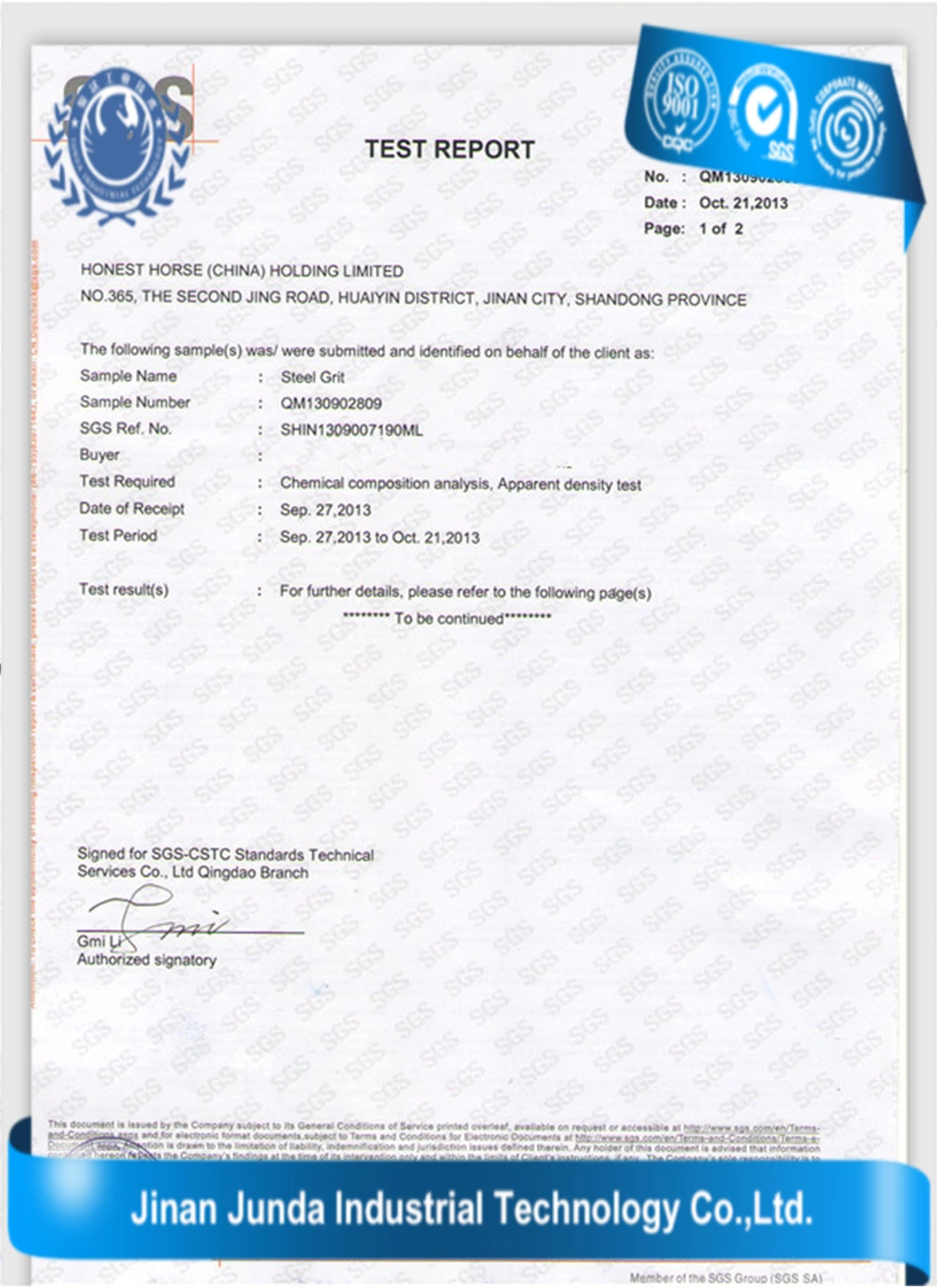

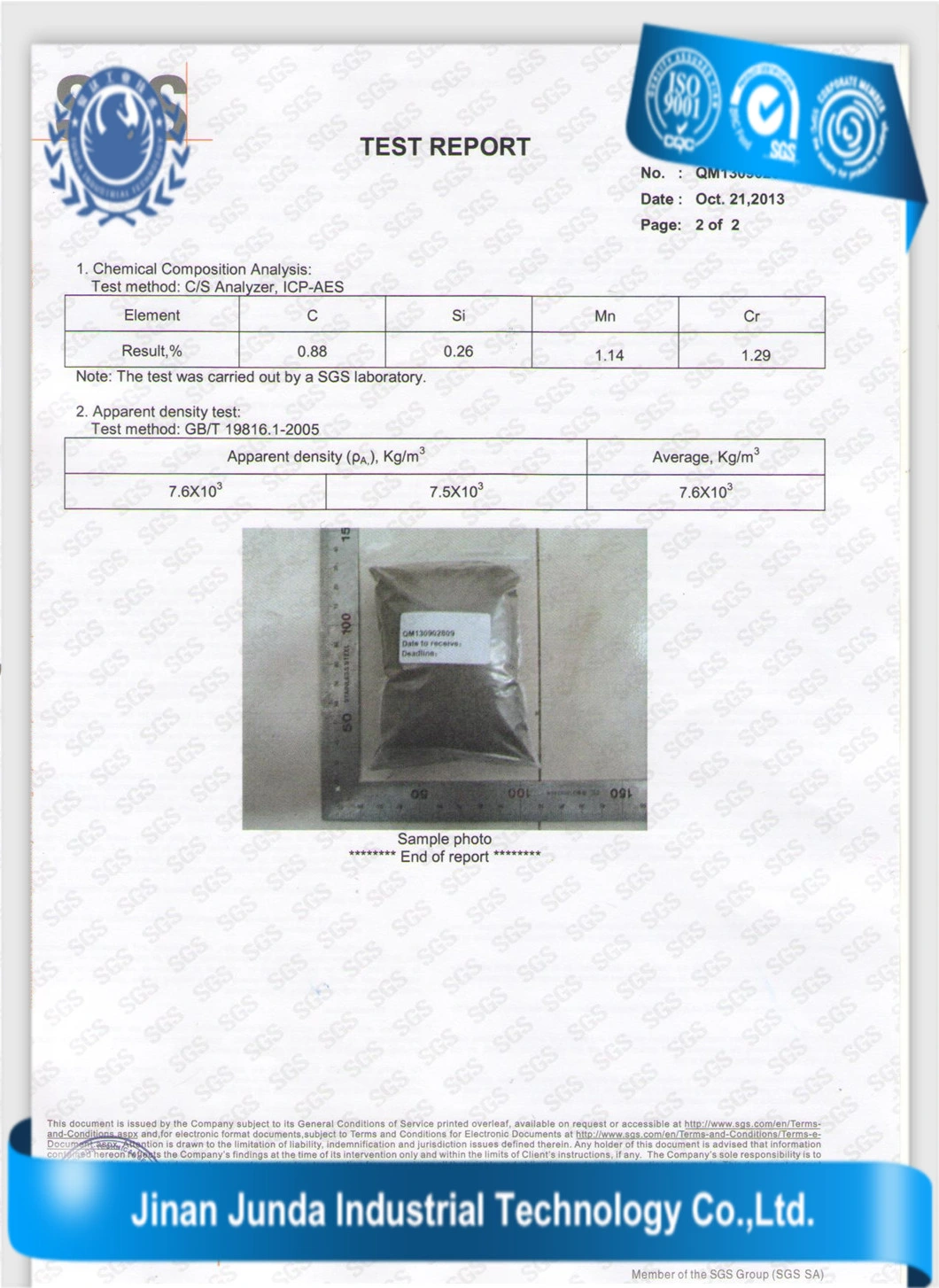

4.SGS AND TESTING EQUIPMENT OF STEEL GRIT

5.PACKAGE:

Our normal packing is 25kg/bag,then 40 bags in one ton bag.1 ton 1 bag.

We can do paper bag and pallet package.

6.PRODUCTION OF STEEL GRIT

7.COMPANY INFORMATION

Jinan Junda Industrial Technology Co.,Ltd established in 2005. We are the professional manufacture and exporter for garnet sand, steel shot, steel girt, bearingsteel grit, glass beads and other abrasives .

Our steel shot, steel grit and bearing steel grit product reach American SAEstandard, they are widely used in shipbuilding, foundry, steel, and automobile,container, machine facture, pipeline anti-corrosion,aviation, granite cutting and soon.

Based on our good qualified product and good service,we have a good reputation among our customers. And we welcome customers all over the world do cooperation with us!

8.FAQ

Q. What is the mode of your payment?

T/T: 50% advance payment and the rest 50% payment oay us when you get the scanned B/L from our E-mail.

L/C:100% irrevocable L/C at sight.

Q. What's the MOQ of your product?

As usual MOQ is 5TONS.Or as your require, we need to calculate the new price to you.

Q. Can you provide the free samples?

Yes, we can send free samples less than 500g to you. Normally, we can send samples to customer by

express, such as DHL,TNT,Fedex,Aramex, etc.

Q. What atandars you carring out for your products?

SAE standard and ISO9001, SGS.

1.PICTURES OF STEEL GRIT

2.SPECIFICATION OF STEEL GRIT

| Project | Quality |

| C | 0.8-1.2% |

| Si | 0.4-1.2% |

| Mn | 0.6-1.2% |

| Cr | 0.26 |

| Hardness | GP 41-50HRC;GL 50-55HRC;GH 63-68HRC |

| Density | 7.6g/cm3 |

| Micro structure | Martensite structure |

| Appearance | Spherical Hollow particles<5% Crack particle<3% |

| Type | G120,G80,G50,G40,G25,G18,G16,G14,G12,G10 |

| Diameter | 0.2mm,0.3mm,0.5mm,0.7mm,1.0mm,1.2mm,1.4mm,1.6mm,2.0mm,2.5mm |

| Application | 1.Blast cleaning: Used for blast cleaning of casting, die-casting,forging; sand removal of casting, steel plate, H type steel, steel structure. 2..Rust removal: Rust removal of casting, forging, steel plate, H type steel,steel structure. 3.Shot peening: Shot penning of gear, heat treated parts. 4.Shot blasting: Shot blasting of profile steel, ship board, steel board, steel material,steel structure. |

3.APPLICATION OF STEEL GRIT

1.Cleaning: blast cleaning, steel blasting cleaning, casting, die casting, forging, forging the shotblast cleaning, the shotblast cleaning steel blasting plate for castings deoxidization, cleaning, cleaning, clean, H section steel, steel structure.

2.Derusting: blast cleaning, blast cleaning, casting rust, forgings, rust removing, forgings, iron removal, steel derusting, h-steel derusting, steel structure derusting.

3.Reinforcement: heat treatment part shot shot strengthening, gear shot strengthening.

Steel grit blasting: shaped steel grit blasting, steel grit blasting, ship plate shot blasting, steel plate spray shot, steel grit blasting.

4.SGS AND TESTING EQUIPMENT OF STEEL GRIT

5.PACKAGE:

Our normal packing is 25kg/bag,then 40 bags in one ton bag.1 ton 1 bag.

We can do paper bag and pallet package.

6.PRODUCTION OF STEEL GRIT

7.COMPANY INFORMATION

Jinan Junda Industrial Technology Co.,Ltd established in 2005. We are the professional manufacture and exporter for garnet sand, steel shot, steel girt, bearingsteel grit, glass beads and other abrasives .

Our steel shot, steel grit and bearing steel grit product reach American SAEstandard, they are widely used in shipbuilding, foundry, steel, and automobile,container, machine facture, pipeline anti-corrosion,aviation, granite cutting and soon.

Based on our good qualified product and good service,we have a good reputation among our customers. And we welcome customers all over the world do cooperation with us!

8.FAQ

Q. What is the mode of your payment?

T/T: 50% advance payment and the rest 50% payment oay us when you get the scanned B/L from our E-mail.

L/C:100% irrevocable L/C at sight.

Q. What's the MOQ of your product?

As usual MOQ is 5TONS.Or as your require, we need to calculate the new price to you.

Q. Can you provide the free samples?

Yes, we can send free samples less than 500g to you. Normally, we can send samples to customer by

express, such as DHL,TNT,Fedex,Aramex, etc.

Q. What atandars you carring out for your products?

SAE standard and ISO9001, SGS.